About Alagobox

Alagobox team is your partner as a One-stop custom packaging box solution provider

Location in China, but ship oversea.

Alagobox team works with our customers to create attractive, eye-catching and stylish rigid paper boxes. Your customized design reflects the quality of your product and brand in a way which grows brand recognition and increases sales!

With 15+ years’ experience in the packaging box industry, Alagobox products cover a wide range of trades. Whether you need custom chocolate packaging boxes, jewelry boxes, cosmetic or beauty packaging boxes, candle packaging boxes, or anything in between – Alagobox does it all.

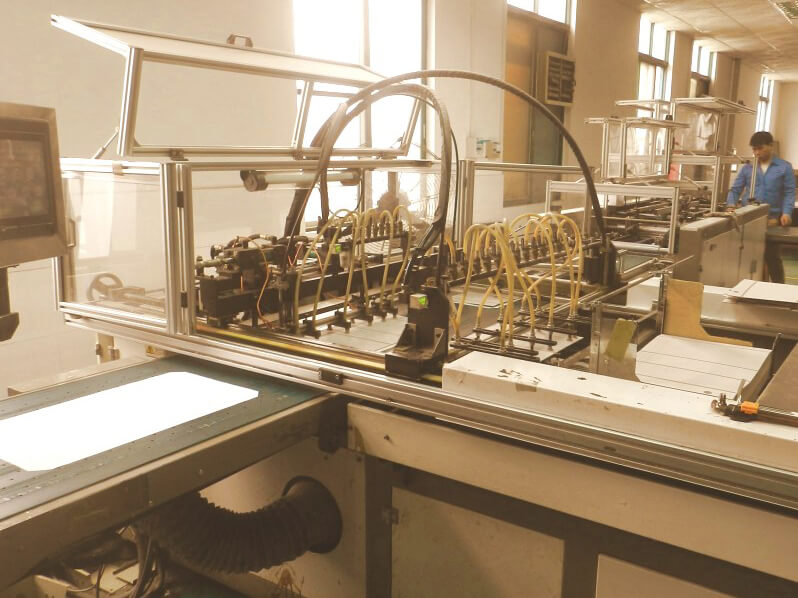

Our design, material selection, sourcing, sampling, engineering, manufacturing, and logistic capabilities allow us to serve many of the top world brands.

Alagobox will do one-stop service to you, from design, sample-making to mass production

Meet our team

Silvia Lee

Sales Manager

Lucy Luo

Marketing Manger

Contact us today

I need a structural design collaborator

Packaging engineers can create a PDF proof or dieline for your custom packaging, whether it is from a scratch or specifications.

Contact usI have a product, service or idea that needs a package

We can provide packaging solution options for your selection. Start one piece sampling order to mass production, you will see your idea to real product by steps.

Contact usI have specs and need a high-quality production partner

We have the knowledge, equipment, and expertise necessary to advice for your packaging.

Contact us